|

3) Assembly of multicore cables Inner coverings and fillers

The inner coverings may be extruded or lapped Material

The materials used for inner coverings and fillers shall be suitable for the operating temperature of the cable and compatible with the insulating material.

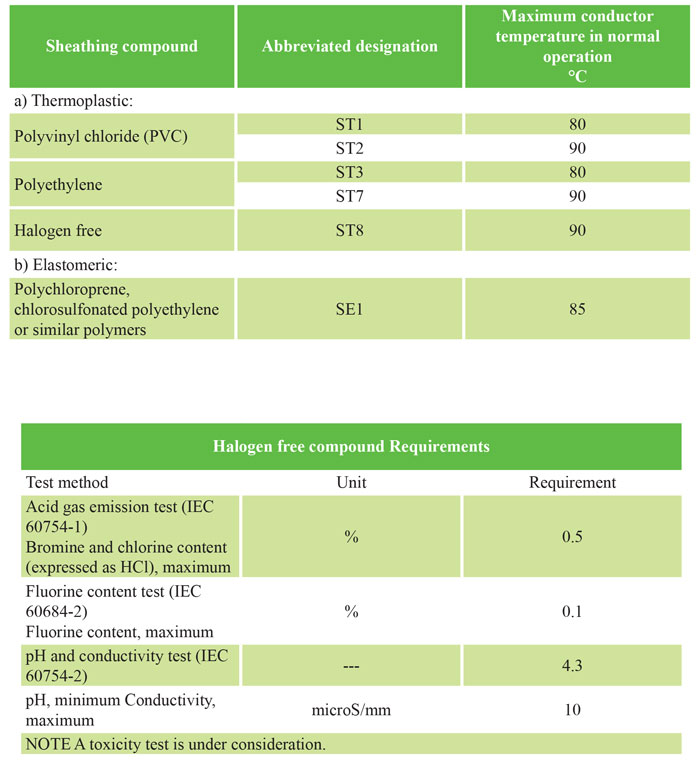

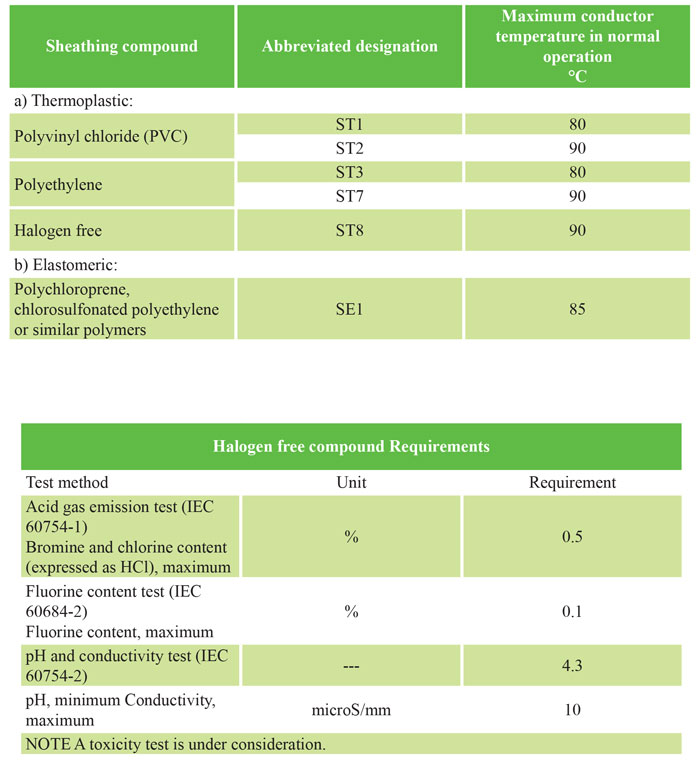

For halogen free cables, the inner covering and fillers shall meet the requirements given in the table named : Halogen free compound Requirements .For cables having neither armour, nor concentric conductor, nor other collective metallic layer the inner covering may be omitted, provided the outer shape of the cable remains practically circular.

4) Screening

All cables shall have a metallic layer surrounding the cores, either individually or collectively .

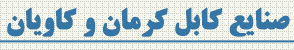

Screening of individual cores in single or three-core cables, when required, shall consist of a conductor screen and an insulation screen. At rated voltage 3.6/6 (7.2) kV cables insulated with PVC shall be unscreened.

4-1) Conductor screen

The conductor screen shall be non-metallic and shall consist of an extruded semi-conducting compound, which may be applied on top of a semi-conducting tape.

The extruded semiconducting compound shall be firmly bonded to the insulation.

4-2) Insulation screen

The insulation screen shall consist of a non-metallic, semi-conducting layer in combination with a metallic layer. The non-metallic layer shall be extruded directly upon the insulation of each core and consist of either a bonded or strippable semi-conducting compound.

A layer of semi-conducting tape or compound may then be applied over the individual cores or the core assembly. The metallic layer shall be applied over either the individual cores or the core assembly collectively and shall comply with the requirements of following Clause.

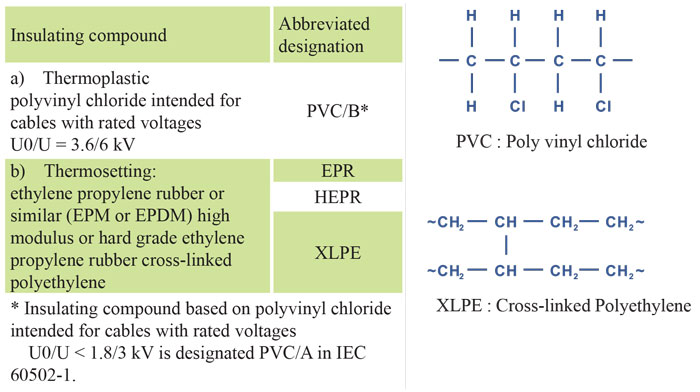

4-2-1) Metallic Screen over Insulation screen

The metallic screen shall consist of one or more tapes, or a braid, or a concentric layer of wires or a combination of wires and tape(s).Gaps in the screen shall comply with the national regulations and/or standards. The dimensional, physical and electrical requirements of the metallic screen

shall be determined by national regulations and/or standards

|

|

4-4) Metallic sheath (Lead sheath)

The sheath shall consist of lead or lead alloy and shall be applied as a reasonably tight-fitting seamless tube.

Lead Sheath is used to protect the cables against penetration of moisture and specially oil and chemicals in petrochemical plants and refineries .

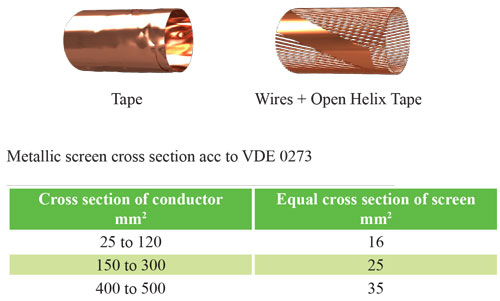

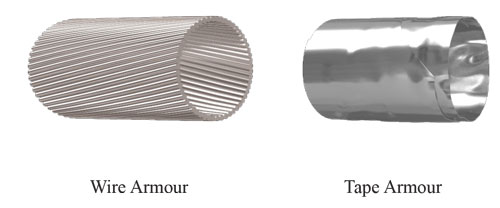

4-5 ) Metallic armour

Types of metallic armour :

The armour types covered by this standard are as follows:

a) flat wire armour

b) round wire armour

c) double tape armour

Round or flat wires shall be of galvanized steel, copper or tinned copper , aluminium or aluminium alloy.

Tapes shall be of steel, galvanized steel, aluminium or aluminium alloy.

Steel tapes shall be hot- or cold-rolled of commercial quality.

The armour of single-core cables for use on a.c. systems shall consist of non-magnetic material, unless a special construction is chosen.

|

|

5) Oversheath

General :

All cables shall have an oversheath.

The oversheath is normally black but a colour other than black may be provided by agreement between the manufacturer and the purchaser, subject to its suitability for the particular conditions under which the cable is to be used.

The oversheath shall consist of a thermoplastic compound (PVC or polyethylene or halogen free) or an elastomeric compound (polychloroprene, chlorosulfonated polyethylene or similar polymers).Halogen free sheathing material shall be used on cables which exhibit properties of reduced flame spread, low levels of smoke emission and halogen free gas emission when exposed to fire.

The oversheath (ST8) of halogen free cables shall meet the requirements given in The table named : Halogen free compound Requirements .

The sheathing material shall be suitable for the operating temperature in accordance with following Table.

Chemical additives may be requested for use in the oversheath for special purposes, for example termite protection, but they should not include materials harmful to mankind and/or the environment.

NOTE : Examples of materials considered to be undesirable include:

Aldrin 1,2,3,4,10,10-hexachloro-1,4,4a,5,8,8a-hexahydro-1,4,5,8-dimethanonaphthalene

Dieldrin 1,2,3,4,10,10-hexachloro-6,7-epoxy-1,4,4a,5,6,7,8,8a-octahydro-1,4,5,8-dimethanonaphthalene

Lindane Gamma Isomer of 1,2,3,4,5,6-hexachloro-cyclohexane.

Sheathing compounds

The maximum conductor temperatures for the different types of sheathing compound covered by this standard are given in following Table .

|